In celebration of National Manufacturing Month, explore Lozier’s plants, people and towns in this series Plant Town History.

“During the Civil War, the story goes that ham and bean soup was thinned out to stretch the meals for troops,” said Butch Heim, Engineering and Quality Manager.

Today, the soups are a little thicker, but bean soup is still served every year on the fairgrounds. Employees at Lozier’s McClure plant get tickets to enjoy a free meal provided by a local fire company. The fairgrounds are so close to the McClure plant that many employees go visit on their lunch break.

A century from the Civil War, Wood-Metal Industries opened its doors in McClure in the early 1950’s. It manufactured metal cabinets for institutional and residential use. Soon after, the company changed its name to Hallmark Industries continuing to manufacture metal cabinets.

In 1964, Hallmark industries drew the attention of Gordon Lozier, and Lozier purchased the 31,000 square foot facility as the first plant outside of Omaha for Lozier.

Photo: McClure in the late 1960’s

Situated between two counties, Scott Spotts, Plant Manager, says McClure is in the ‘sweet spot’ for people living around McClure, with most employees living within 30 minutes east or west of the plant.

“I don’t want to be anywhere else but here,” Spotts said. “Once I joined Lozier, I can’t think of anything that would make me want to leave. The team in the plant, the other locations, the executive team; it’s been a great family environment to work for all of these years.”

In the 1990’s, McClure began its specialization in Wire grid manufacturing. Along the way, McClure has grown through six expansions to 111,000 square feet, the smallest of Lozier’s facilities.

The Schlatter 1 was McClure’s first automated piece of equipment to automate the Wire Frame welding. Moving away from manual Pick and Place Welding jigs under a single point welder meant that several frames could be completes as once and then split apart to size. With its success, a second Schlatter was purchased before the end of the century.

“We are the only Wire Manufacturing plant within Lozier,” said Heim. “While Joplin and Middlebury had wire production for a number of years, our processes are more capable and unique. We started drawing our own wire in 2009 and now we meet most of our wire demand through that process.”

New capabilities came to McClure with the LORS, which was used to weld thousands of SS_WGs for a customer in Canada. Following the purchase of a few more machines, McClure now has seven Grid Welders for wire grid production.

“For the longest time, we were the only plant that did fully-welded cabinet construction,” Spotts said. “We still do mostly fully welded cabinet construction, and McClure also used to make large desks and cabinets for the government a long time ago.”

Tallying the leadership team’s experience reaches all the way past the Civil War, at more than 300 years of service at Lozier.

“We have a lot of senior people at Lozier,” Heim said, “but we have a very mixed group now. We get a lot of talented people out of high school who have done internships with us and stay on.”

Wire Grid welding is a complex process and there are few who come to Lozier with that skillset. McClure looks for talented people who are willing to be trained in the process. Much of McClure’s talent comes from the country, “There aren’t many big cities here,” Heim said. “But our location attracts people and many have family and friends that work or previously worked for Lozier.”

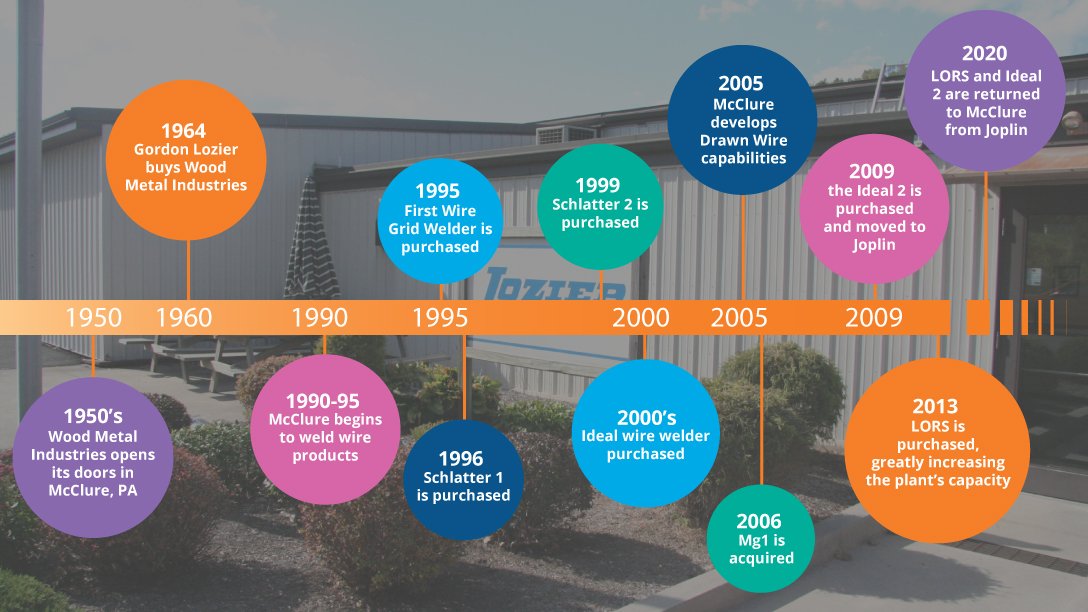

Image: a timeline of McClure’s history

The best thing about McClure for the employees? Camaraderie.

“We have close-knit teams across our departments,” Heim said. “Lozier is a strong company that presents challenges and opportunities for growth. We have many people come up through production and into our technical Maintenance and Tool & Die roles.”

The close-knit teams are no accident, McClure has had a number of employees like Kim Weader, Candy Burkey, Bethani Hocker, Christy Mallery, Sharon Hess, Jarrod Plummer, Pharis Trutt, Jerry Wagner and others work on the production floor and in the office and make intentional efforts to connect and have conversations with everyone.

“The family atmosphere makes our work more enjoyable,” Spotts said. “Butch interviewed me, and at McClure, you develop friendships, stay close with people and that makes you want to stay.”