In celebration of National Manufacturing Month, explore Lozier’s plants, people and towns in this series Plant Town History.

“There is comfort in seeing many of the employees here with 20 plus years for experience,” said Bill West. “People here have spent the majority of their life with their co-workers; there’s a family atmosphere here. But before Lozier, we could have been shut down.”

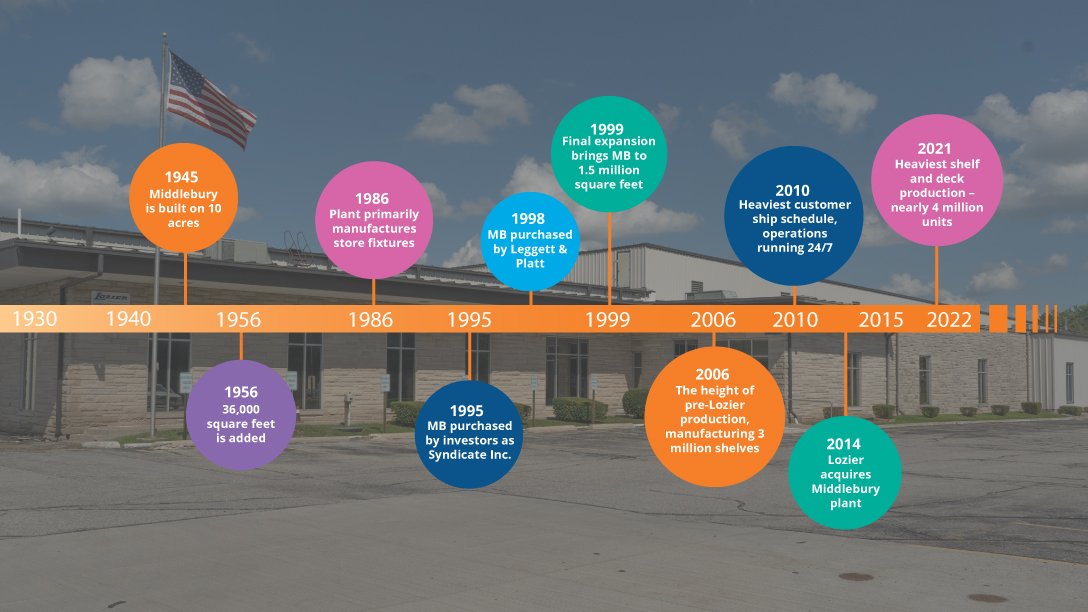

From humble beginnings, the Middlebury plant started out with 7,000 square feet of space creating tire retread blades in 1945. The O.S. Keene Machinery Company then diversified into the popcorn market, manufacturing popcorn poppers along with machine repair parts and the blades.

By 1956, the plant had added 43,000 square feet of space. Still a private company, the name changed to Keene Products and then CTS before it began manufacturing, but not selling, store fixtures.

Left: a popcorn maker manufactured in Middlebury. Right: Mark Cook, Plant Manager, shows off the popcorn maker.

The 80’s were a boom for Middlebury with the fixture industry changing the game for the manufacturing facility.

“In the 80’s this was the place to work,” said Chris Bunten, Industrial Engineering Supervisor. “We didn’t need to promote our jobs, you had to know someone here to get an interview.”

As Middlebury expanded, they still held a small job shop perspective, competing with everyone and anyone.

“If a customer needed 10,000 shelves by Tuesday, we would get it done,” Bunten said. “When our competitors wouldn’t be able to pull off a job, we would get the call. Our managers would get together and it was like clockwork for us as we pulled it together.”

America’s premier retailers were all purchasing products manufactured in Middlebury. The facility also grew to become a single source supplier for some companies, with the philosophy shifting from build-to-order to building on demand or a forecast system. This was also when plant leaders computerized the Middlebury operation with the AS400, an advanced version of the mainframe which held order and processing data.

Many still remember Middlebury’s ‘good ole years’ in the 80’s and 90’s, a time of mass expansion and technological improvements.

“It was the height of growth for Middlebury’s machine and product capabilities,” Bunten said. “We had many new products and processes that included in-house manufactured machines much like Lozier does today.”

The operation instituted special quality programs, including a “Zero Defects” and “Do it Right the First Time” programs, rewarding employees for excellent work. The plant even had developed an initiative where operators cross-trained every piece of machinery, ensuring Middlebury had staff to run any machine in any plant across all three shifts.

“Middlebury has always had a can-do attitude and understanding of regular changes,” Bunten said. “Our job shop products were ever changing as well as the customers we served and companies we competed against.”

The 90’s also included a number of sales and purchases of the company following the founder’s death, eventually coming under Lozier’s ownership. The plant’s previous owner, Leggett & Platt, hoped to become a retail store fixture conglomerate, with Middlebury being the first step toward that goal.

Moving into the 2000’s, Middlebury positioned itself well, with it’s final of 26 expansions bringing the plant to its current 1.5 million square foot size. In just over 50 years, the plant had increased its acreage from 10 acres to 100 acres.

Despite its location in a town of just 3,500 people, the plant easily employed 1,200 staff across multiple shifts, manufacturing three million shelves and decks in 2006.

In 2010, Middlebury produced and shipped so much product, it even used five off-site warehouses and used 120 lift trucks. For 24 hours, seven straight days, Middlebury shipped truckload after truckload to a single customer.

“At the beginning it was ship, ship, ship,” Bunten said. “Everyone was in the DC, packing or pulling boxes, or just sweeping the floor of all of the debris. By the Thursday, some of us went back to building, as the trucks were just waiting there, empty, waiting for product.”

The line of trucks was more than two miles long, and the retailer brought in their own traffic coordinators, operating out of a large tent in the parking lot. For comparison, Middlebury today is around 60 percent distribution center and uses around 50 lift trucks.

“It’s projects like these, working round the clock to deliver, that pull us all together,” West said. “We could have been shut down, but Lozier chose to put money in Middlebury because they saw how the people here have the ability to make an impact and work as a team. Pulling projects together is part of our culture.”

Lozier acquired the Middlebury Plant from Leggett & Platt in 2014, bringing in funding and process improvements.

“After the 90’s, we’d stopped evolving and our technological growth started waning,” Bunten said. “Lozier brought a huge influx of vision, improvements and brought Middlebury up to speed with technology.”

With its massive plant space, shelves traveled nearly two and a half miles around the plant during their building lifecycle. Lozier brought that process down to only 1,000 feet of traveling distance for a shelf and doubled its ability to store shelving. Lozier’s plant improvements resulted in Middlebury’s highest record of of shelf and deck production in a year, with nearly four million units manufactured.

“Our labor force is very adaptable,” Bunten said. “We would push and pull labor to whatever product was heavy-hitting. Along with lots of high volume, short-lived projects, Middlebury was forced to get good at time-to-market and quick customer response and adaptability.”