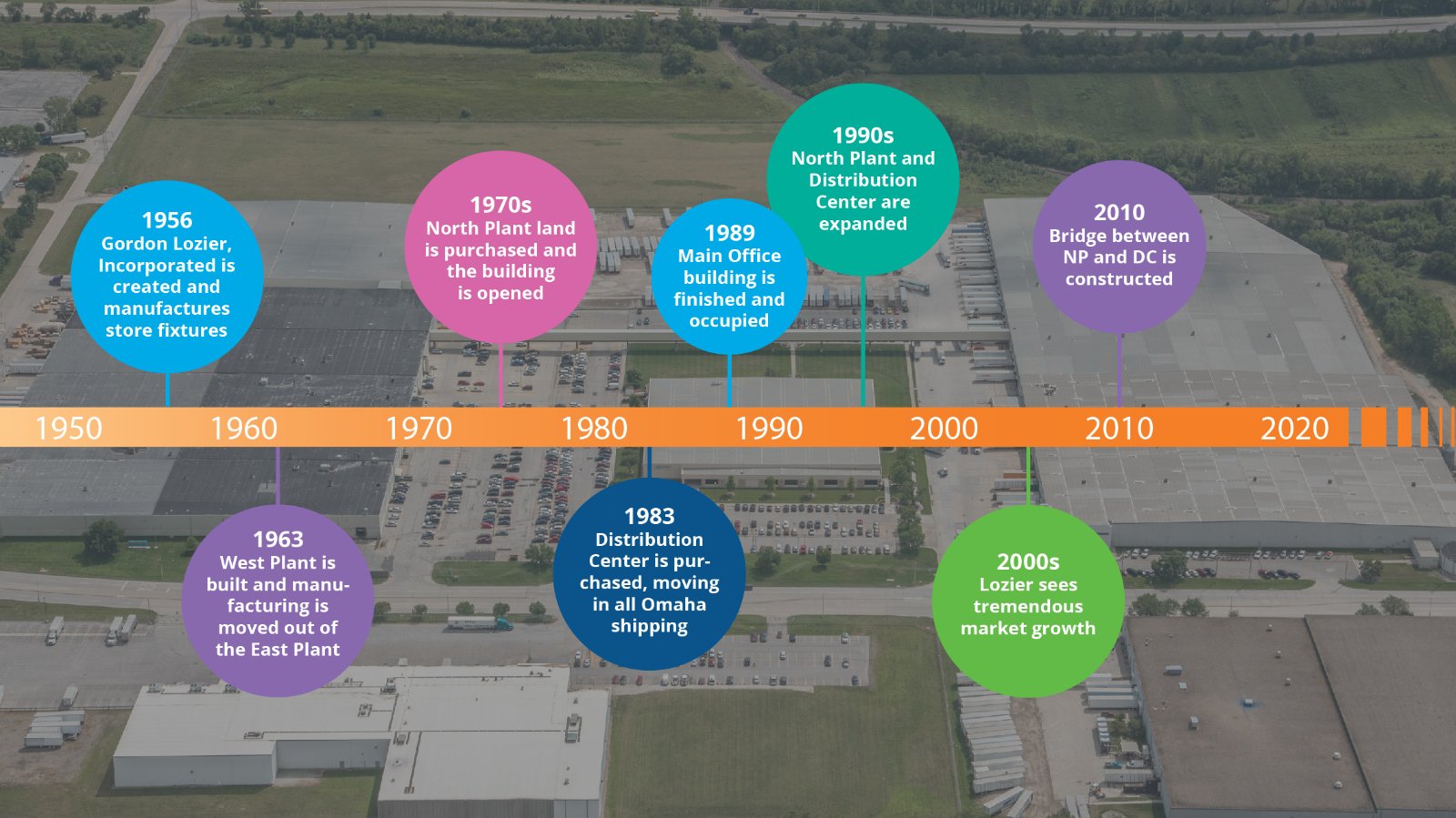

An aerial view of the North Plant, Main Office and Distribution Center, with a cargo bridge connection between the North Plant and Distribution Center.

“It was a real shock, when I visited the old building, it was unbelievable,” said Ginny Willingham, Executive Assistant. “People were dressed in jeans and I came in with a three-piece suit and the works. I was stunned at the casual atmosphere, but it was always a great and fun company.”

Gordon Lozier started Gordon Lozier, Incorporated, after his son, Allan Lozier designed a store fixture more structurally sound than anything else on the market. The shelving business was built off of Gordon Lozier’s refrigeration service and distribution company. Lozier began manufacturing store fixtures in Omaha in 1956 in what was known then as the East Plant. Lozier occupied the bottom floor of the North Omaha building with 25 employees. Eventually the upper floor was taken over to be used as office spaces.

Production moved from the East Plant once the West Plant was built a couple blocks away in 1963. The entire East Plant was then turned into an office area.

“When the head of the plants came through the offices smoking a pipe, he would just leave this stream of smoke,” Willingham said. “Another guy in our sales department smoked cigars. I would go home at night and hang my clothes outside because they smelled so bad.”

Lozier’s East Plant.

In the 70s, the land for the North Plant in North Omaha was purchased from Union Pacific Railroad and the North Plant was built. Backline, shelving and distribution were moved to the new facility.

What Willingham remembers well is the call board that could be seen from the one office with a computer and a giant glass wall, overlooking the office area. On the far end was a call board that lit up when callers were waiting to be answered.

“Wherever he was in the world, Allan would call in every day to learn about orders and back orders, and I would need to have that information ready,” Willingham said. “If his calls rang for too long, he would ask the Customer Service Manager why it took so long.”

A Lozier report from 1992 boasted that “98 percent of Lozier calls are answered by the second ring,” a testament to Allan Lozier’s daily calls.

Willingham, who started at Lozier 41 years ago, has worked with the three generations of Lozier CEOs and the many other executive leaders. Soon after she started, the move to the Pershing Drive campus was beginning.

In 1983, the Distribution Center was purchased from General Tire and all Omaha shipping was moved and the manufacturing capabilities in the North Plant were expanded.

The Main Office was finished and occupied in 1989, and to Willingham’s joy, smoking was not allowed in the new building. The old East Plant was donated to the Omaha Housing Authority, leaving the West Plant the only location near where Lozier was founded.

Lozier’s West Plant.

To Larry Higgins, today’s West Plant Manager, being in one of Lozier’s oldest locations doesn’t stop their drive for improvement.

“The West Plant workforce desires to be engaged and is always up for a challenge and willing to get behind a continuous improvement initiative,” Higgins said. “They are a dedicated team that truly enjoys what they do and take pride in the results of their contributions. This provides us the agility and flexibility to take on whatever is needed to support the business.”

While the West Plant produces Lozier’s core gondola product, it is frequently used as a test facility, trialing products and processes.

“Whether it’s supporting T-system Uprite production or the changes necessary to incorporate Oracle in our day-to-day activities, the West Plant is always ready to support the growth and success of Lozier,” Higgins said.

Because of its increasing growth and supplying 80 percent of the Nation’s retailers, the 1990s brought an expansion of the Distribution Center and North Plant. As a result, the 90s and 2000s saw tremendous growth and output capability, helped by an increased investment in technological advancements including lasers, punches and robots. It also brought continued investments in new technology, while optimizing existing equipment to increase Lozier’s capacity to meet the growth in demand.

The final expansion in Omaha’s facilities was a cargo bridge connecting the North Plant and Distribution Center. Finished parts travel across the plants for faster packing and shipping times.

“Lozier is very different than when I started,” Willingham said. “I have always been exposed to a lot of what is going on in the world, because Allan would devour any kind of information and I would follow along. The way we are doing things now is new, different, and I think it’s all good.”